0553585028: How to Find Cross-Reference and Datasheet Fast

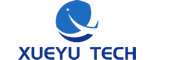

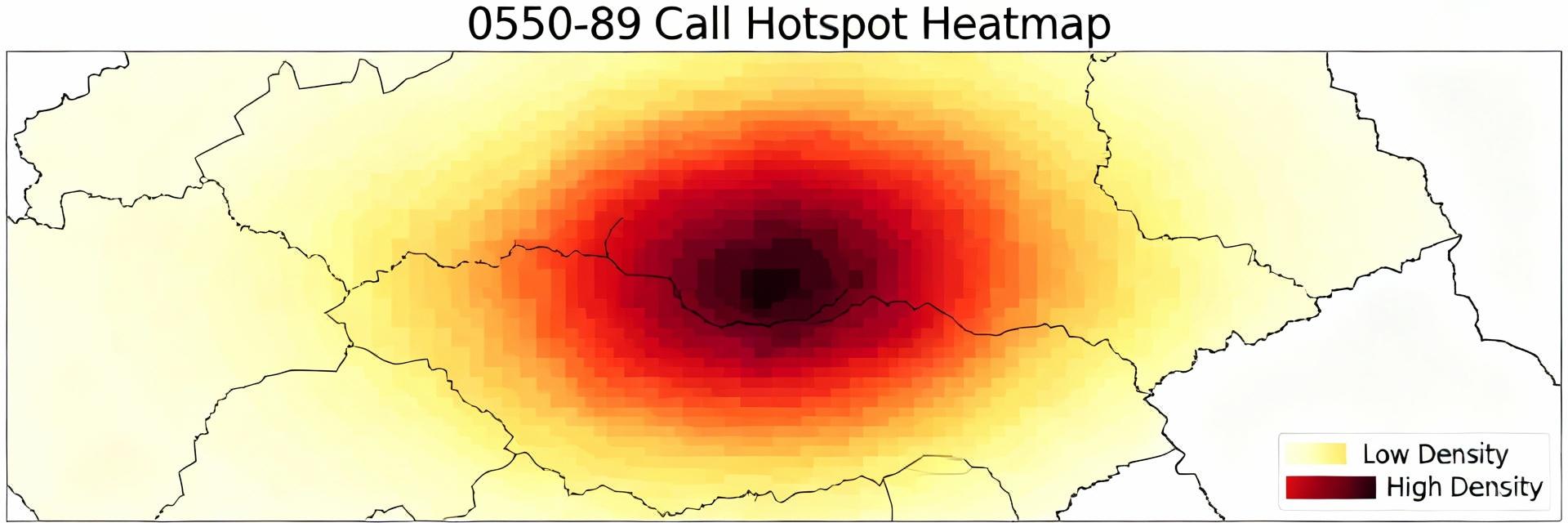

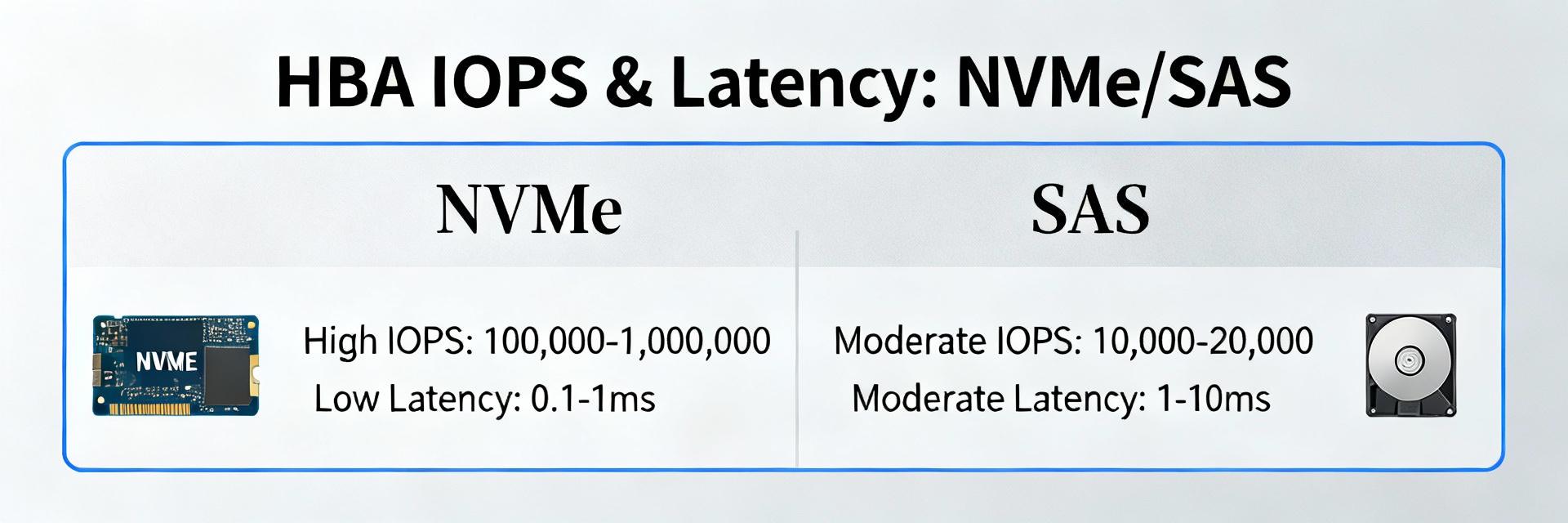

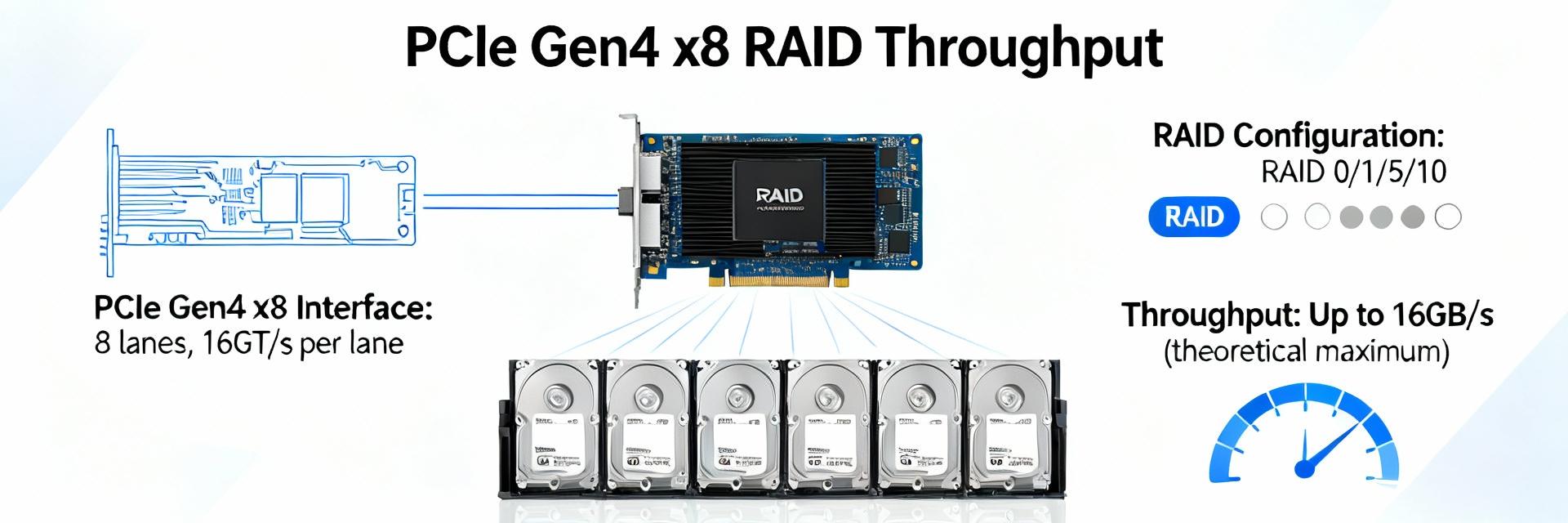

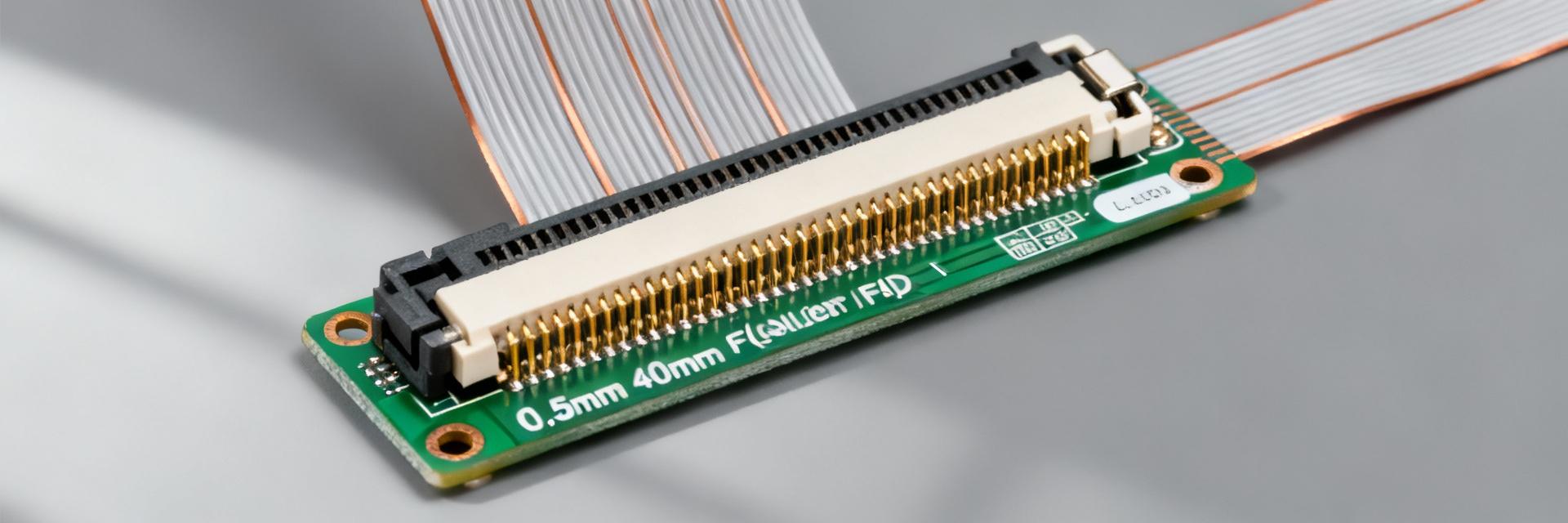

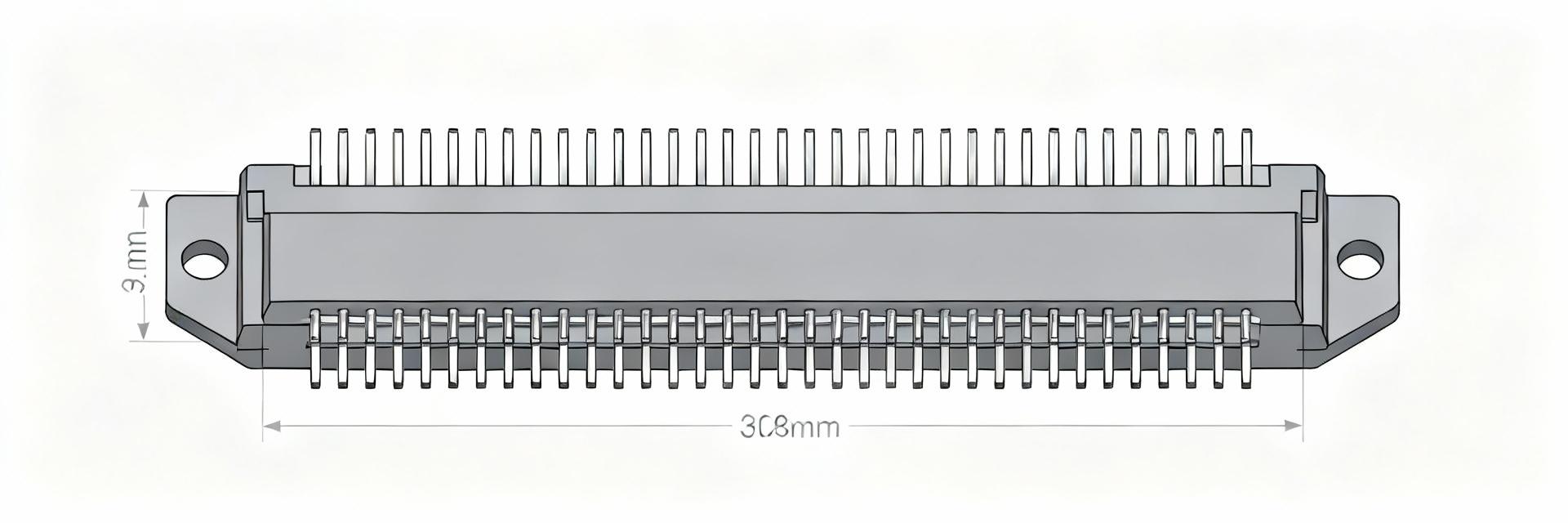

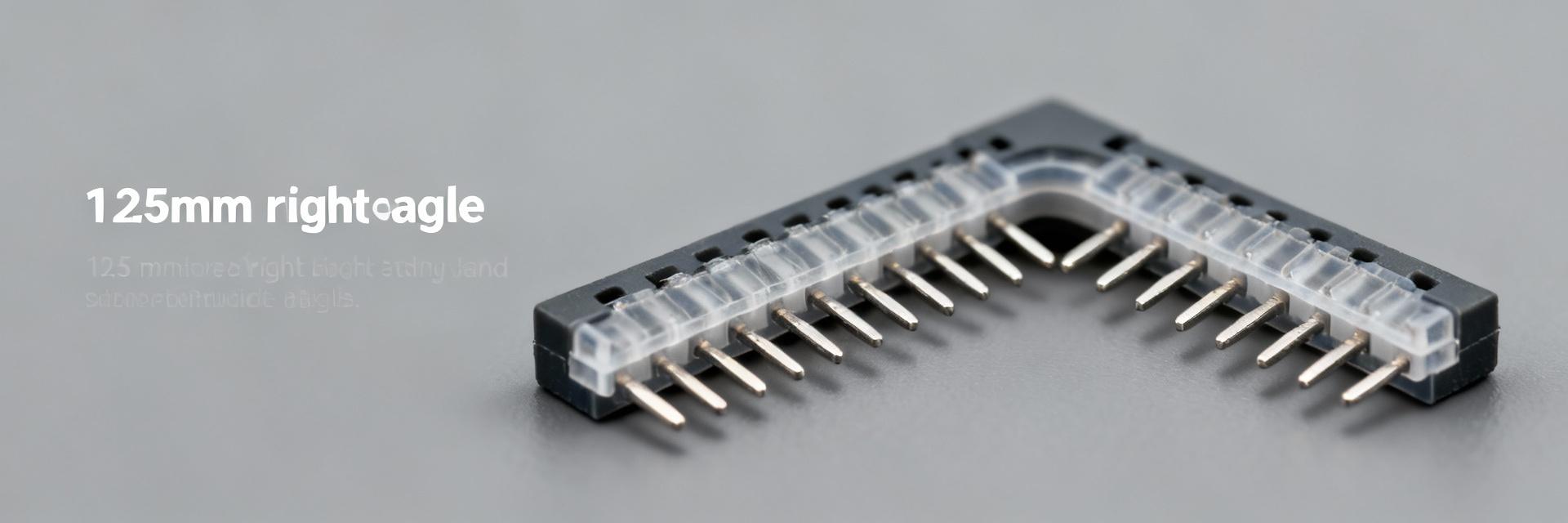

This guide delivers a fast, repeatable process to locate a datasheet and cross-reference for 0553585028, aimed at engineers and buyers who must resolve obscure or legacy parts quickly. It provides seven targeted search shortcuts, a compact verification checklist, and a five-step replacement workflow you can reuse in BOM triage and prototype work. Many parts are hard to locate because they are obsolete, internal house numbers, or published under alternate formats; that makes reliable verification essential. Read on to learn how to find datasheet PDFs efficiently, detect lifecycle flags, and confirm true equivalence before you place orders or approve a substitute. Quick background: what the part number format suggests What to expect from the datasheet Point: A usable datasheet typically contains a concise part description, electrical ratings, pinout, and footprint drawing. Evidence: Standard spec documents list max voltages, currents, and mechanical dimensions. Explanation: When you open a candidate PDF, look first for part family name, absolute maximums, typical curves, and a mechanical drawing that shows pads and tolerances—these determine cross-reference viability for 0553585028 datasheet searches. Why some part numbers are hard to find Point: Difficulty often comes from obsolescence, internal catalog numbers, or truncated legacy IDs. Evidence: Search results may show few matches, inconsistent numbering, or only archived pages. Explanation: Broaden queries to include variations (leading zeros, hyphens, vendor-less identifiers) and focus on functional attributes rather than an exact-match string when an exact PDF fails to surface. Fast lifecycle & authenticity checks before you trust a cross-reference Detecting End-of-Life (EOL) Status Point: Quick lifecycle detection saves time and risk. Evidence: Red flags include search snippets with “obsolete” or “end-of-life,” absent recent listings, and old revision dates in PDFs. Explanation: Capture catalog notes, spec revision timestamps, and any EOL markers before you accept a substitute; treat a lone undocumented cross-listing labeled as a candidate for 0553585028 cross-reference with caution. Authenticity Checks Point: Verify PDF metadata and completeness to rule out false matches. Evidence: Authentic datasheets include publisher metadata, complete electrical tables, and dimensional tolerances. Explanation: Open PDF properties to confirm publisher and creation date, ensure electrical curves and full pin tables are present, and flag documents that omit tolerance or show inconsistent part numbers internally. 7 fast search queries & tools that find datasheets 01. "0553585028 datasheet" 02. filetype:pdf 0553585028 03. "0553585028 pinout" 04. "0553585028 cross reference" 05. site:*.edu "0553585028" (Academic archives) 06. "0553585028 footprint" 07. Augmented: "0553585028 right-angle connector" Specialized Tactics: Use parametric resources beyond plain search. Filter by pitch or contact count in component databases. Check web archives (Wayback Machine) for legacy manufacturer pages. Image matches often confirm mechanical shape when text hits are scarce. How to verify a cross-reference is truly equivalent Equivalence Criticality Score Electrical Limits (Voltage/Current) 100% Match Required Pinout & Polarity 100% Match Required Mechanical Footprint 95% Match (Tolerances vary) Practical Validation: Export footprint files to compare land patterns, request samples for bench testing, and review revision histories. When in doubt, choose a candidate with equal-or-better ratings or design a mechanical adapter as a mitigation strategy. Fast action checklist & replacement workflow STEP 1 Run Augmented Searches STEP 2 Capture Datasheets STEP 3 Apply Checklist STEP 4 Shortlist & CAD Sync STEP 5 Release & Test Audit Category Requirement for 0553585028 Confidence Level Electrical Spec Voltage/Current ratings must meet or exceed original. High Mechanical Pad alignment and height clearances. High Lifecycle Active/Preferred for new designs. Variable Summary Target exact-match queries first, then broaden to augmented terms and image searches; this yields the fastest wins when you need to find datasheet artifacts and initial footprint images. Use quick lifecycle and PDF-authenticity checks—revision dates, metadata, and complete electrical/mechanical tables—to filter unreliable matches before you trust a cross-reference. Apply the spec-by-spec checklist and the five-step workflow: search, capture, checklist, shortlist, document. Keep a simple BOM checklist to prevent surprises in production. Frequently Asked Questions How can I confirm a found datasheet is the correct 0553585028 part? Confirm by matching three things: identical electrical absolute maximums, exact pinout mapping, and a footprint drawing with matching dimensions and tolerances. Verify PDF metadata and revision date. If any key parameter or pad spacing differs, treat it as non-equivalent until samples or CAD confirmation prove otherwise. What are the fastest queries to run when I need to find datasheet quickly? Run exact-match queries first, then augment: "0553585028 datasheet", filetype:pdf 0553585028, "0553585028 pinout", "0553585028 equivalent", and site: filters for archived pages. Add package descriptors like "2-pin" or "right-angle" to narrow results if the exact string produces noise. When should I reject a cross-reference candidate for a BOM item? Reject if the candidate lacks matching electrical maximums, has a different pin mapping or incompatible footprint, or if the datasheet lacks reliable revision metadata. Also reject if the part shows EOL indicators without a clear qualified replacement; document the rejection and continue the search for a verified substitute.

2026-01-28 10:38:07