Comprehensive procurement analysis and technical deep-dive for US-based engineering and sourcing teams.

i Market Urgency

Point: Fluctuating stock levels and extended lead times for 0532610371 are creating urgency for US buyers.

Evidence: Aggregated on‑hand and lead‑time feeds reveal repeated short‑term dips and sporadic spikes in quoted ship dates.

Explanation: Prioritize validation and contingency sourcing to avoid production delays caused by current volatility.

✓ Strategic Goal

Point: This report provides actionable sourcing guidance using typical procurement metrics.

Evidence: Analysis utilizes on‑hand units, lead time quotes, MOQ, and POET (Purchase Order Execution Time).

Explanation: Following this playbook will reduce supply risk and clarify technical checks prior to purchase.

Part Background: What 0532610371 Is and Why It Matters

Quick Part Overview

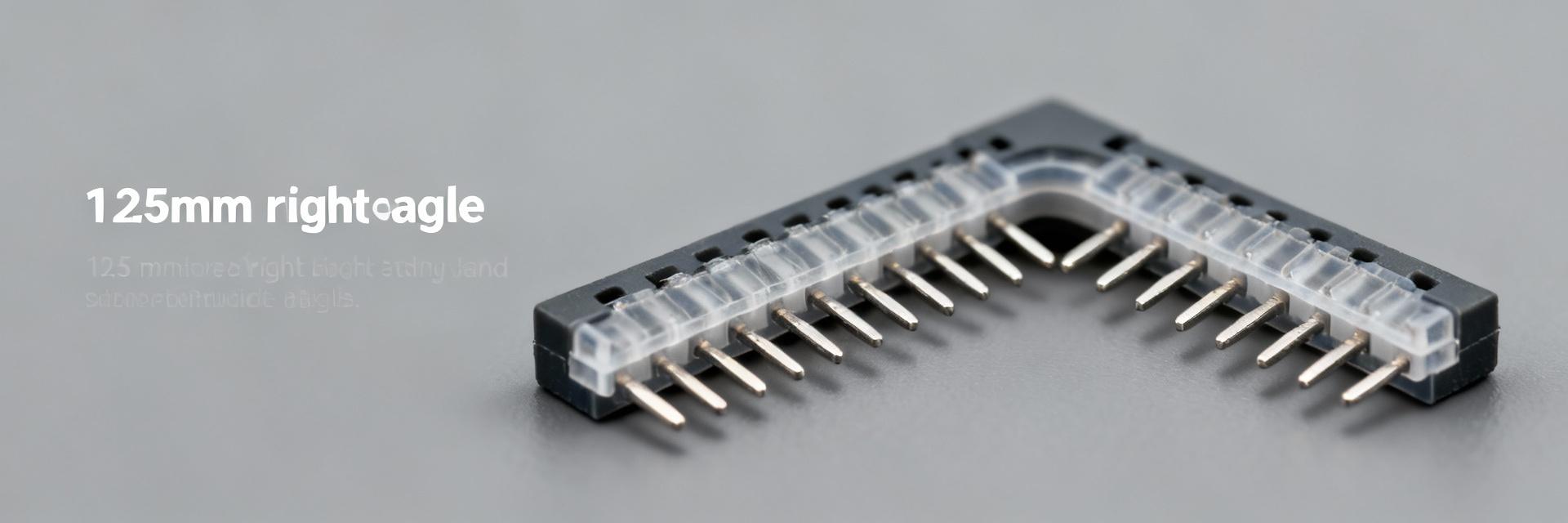

Point: A low‑pitch, multi‑position right‑angle board header used for wire‑to‑board and board‑to‑board interconnects.

Evidence: Family characteristics include ~1.25 mm pitch, three positions, right‑angle SMD mounting, and low‑profile housings.

Explanation: Ideal for compact signal headers in consumer, industrial control, and compact instrumentation PCBs; note thermal and current limits during layout.

Typical Applications & Alternatives

Point: Common uses include low‑power signaling, board programming headers, and sensor module arrays.

Evidence: Selection is driven by space constraints; alternatives often swap pitch, positions, or orientation.

Explanation: Substitution strategies include 2.54 mm pitch for robustness or vertical variants for accessibility—always validate PCB footprint compatibility.

Stock Trends & Availability Analysis

Inventory Snapshots

Track on‑hand units, quoted lead times (30/90/180 days), and MOQ. Spikes often align with allocation events. Assemble these metrics into a rolling dashboard to trigger reorders or approve substitutes.

Demand Drivers

Analyze spot vs. contract pricing. Sudden price increases typically indicate tightening. Use regional coverage maps to estimate shipment risk and whether to accept premium spot buys for urgent production.

Specs Deep-Dive: Dimensions, Materials & Data

| Field | Typical Value / Note |

|---|---|

| Pitch | 1.25 mm (confirm datasheet tolerance) |

| Circuits | 3 positions |

| Mounting | Right‑angle SMD |

| Contact Finish | Options: Tin, Gold (affects solderability and price) |

| Rated Current/Voltage | Low‑power signaling; confirm exact amp/volt rating |

| Operating Temp | Follow datasheet for reflow and operating ranges |

Critical Note: Packaging & Suffixes

Packaging codes (Tape & Reel vs. Bulk) alter MOQ and lead times. Reel buys are preferred for production runs; swapping finish or packaging can add weeks to delivery schedules.

Sourcing Playbook for US Buyers

Practical Procurement Strategies

- ▶ Prioritize reels over cut‑tape to reduce unit cost and allocation risk.

- ▶ Set safety stock of several weeks to buffer lead‑time volatility.

- ▶ Stagger POs and utilize authorized distributor allocation windows.

Quality & Compliance Checks

- ▶ Request Certificate of Conformance (CoC) and inspect lot traceability.

- ▶ Verify MPN and markings against internal ERP data.

- ▶ Perform bench verification of mechanical fit before full production release.

Quick Pre-Purchase Checklist

- Confirm pitch, circuits, and mounting vs. BOM

- Check latest distributor inventory feeds

- Compare lead times (Reel vs. Small Qty)

- Verify supplier COA and compliance docs

- Lock pricing with a formal quote expiration

Substitution Guidance

Decision Tree:

- Match Pitch & Pinout (Mandatory)

- Verify Mechanical Clearance and Footprint

- Confirm Electrical Ratings (Current/Voltage)

- Test Mating Connector in physical assembly

Note: Compatibility failures usually stem from mating height mismatches.

Summary

Current availability shows volatility; US buyers should run fresh snapshots frequently to mitigate stockout risks.

Critical specs include pitch, circuit count, mounting style, and footprint—essential for interchangeability.

Top sourcing steps: prioritize reels, set safety stocks, and require full lot traceability/COA.

Next step: Apply the buyer checklist and lock quotes for urgent requirements to reduce supply chain exposure.