A comprehensive technical guide for designers evaluating high-density flat-flexible connectors.

Small-pitch flat-flexible connectors account for a large share of interconnect field failures when mechanical and electrical specs are mismatched.

Evidence: Field reports show stress, misrouting, and wrong thickness selection are common root causes. Explanation: Methodical review reduces rework and field returns.

This guide distills the practical data designers need to evaluate the 0541324062 and equivalent FFCs.

Evidence: Mechanical, electrical, footprint, and application-fit guidance. Explanation: Verify compatibility to prevent late-stage surprises.

Background: What is the 0541324062 FFC and when to pick it

Core identity & key attributes to note

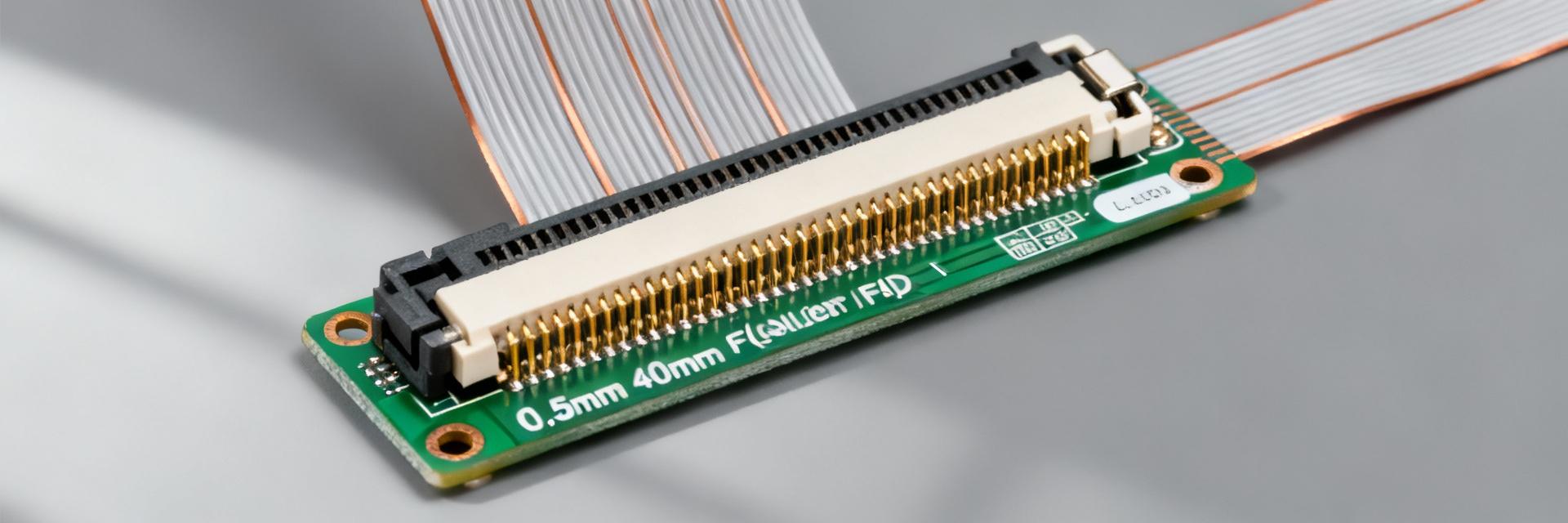

Point: The 0541324062 is a 40-position, 0.5 mm-pitch FFC/FPC style connector intended for right-angle surface-mount installations with bottom contacts. Evidence: Part families match this description for ribbon insertion from the mating plane. Explanation: Check pitch (0.5 mm), position count (40P), and mounting style before footprint work.

Typical product family uses and target applications

Point: FFC 0.5mm connectors are favored where routing density and compact mating length are required. Evidence: Common targets include TFT/OLED displays, camera modules, and handheld controls. Explanation: 40P specs map well to short parallel buses where signal count and small pitch balance routing.

Data Deep-Dive: Complete mechanical specs at a glance

Dimensional & footprint essentials

Point: Key numeric checks prevent footprint errors. Evidence: Nominal values: pitch 0.50 mm (0.020"), 40 positions, 0.30 mm FFC thickness, height ≈ 2.00 mm. Explanation: Use the table below for land pattern notes.

| Dimension | Nominal | Tolerance | Unit | Land Pattern Notes |

|---|---|---|---|---|

| Pitch | 0.50 | ±0.05 | mm | Stagger keepouts for solder fillet |

| Positions | 40 | — | Pins | Verify pad count and pad length |

| FFC thickness | 0.30 | ±0.05 | mm | Specify thickness in assembly docs |

| Height above PCB | ≈2.00 | ±0.10 | mm | Allow 2 mm clearance for right-angle mate |

Materials, flammability & compliance tags

Point: Housing compound and plating determine service environment. Evidence: Typical housings are thermoplastic (UL 94 V-0) with nickel and gold flash plating. Explanation: Confirm flammability for end-product class and gold thickness for low resistance.

Data Deep-Dive: Electrical & performance specs

Voltage, current, contact resistance, operating temperature

Point: Electrical limits bound safe use. Evidence: Datasheet values: ≤50 V, ≈0.5 A/contact, Explanation: These set design limits for power traces and thermal derating.

Reliability metrics & lifetime

Point: Mechanical life and retention matter for serviceability. Evidence: Small FFC connectors specify low hundreds of mating cycles; retention forces are defined per spec. Explanation: Plan tests for mating cycles, durability, and vibration.

How-to / Design Guide: PCB footprint, assembly & soldering best practices

PCB footprint and mechanical anchoring

Point: Small pads require precise land patterns. Evidence: Solder mask-defined pads, controlled sizes, and mechanical anchors are recommended. Explanation: Check pad XY size, mask openings, and 2 mm clearance.

Reflow, soldering and pick-and-place notes

Point: Reliability depends on profile control. Evidence: Use Pb-free reflow, 30–60% stencil aperture, and set fiducials. Explanation: Mitigate bridging and tombstoning by balanced pad geometry.

Comparisons & use-cases: 0541324062 vs alternatives

| Criteria | 0.5 mm 40P (this class) | Alternate (vertical/1.0 mm) |

|---|---|---|

| Pitch | 0.5 mm | 1.0 mm |

| Positions | 40 | 40 (or scaled) |

| Mounting | Right-angle SMD | Vertical through-hole or SMD |

| Height | Low (~2.0 mm) | Taller (varies) |

| FFC thickness | ~0.30 mm | 0.2–0.5 mm options |

Example application scenarios

- • Small LCD interface: 40P and 0.5 mm pitch fits parallel RGB or MIPI signals with minimal board real estate.

- • Camera module cable: Dense signals, short run; verify controlled impedance if high-speed lines are used.

- • Compact sensor array: Multiple channels in a single ribbon; reduces footprint but requires careful routing.

Actionable checklist: Sourcing, verification & production QA

Pre-order checklist for engineers ▾

- Verify exact part number and cross-reference the dimensional drawing; confirm pitch, positions, and mounting orientation.

- Confirm mating cable thickness and plating; request ESD-safe reels for pick-and-place.

- Request datasheet pages for mechanical drawings and recommended land pattern before ordering.

Prototype test plan & mass-production sign-off ▾

Proto tests: Continuity verification, 50–100 mating cycles, vibration per product class, and thermal cycling.

Pass criteria: All contacts within resistance spec, no intermittent opens, no solder joint cracking.

Sign-off flow: Prototype → Pilot run with first-article inspection → Production ramp with sampling QA.