Evidence

The device tested exhibited mean capacitance drift under DC bias and a small percent change after extended high-temperature bias exposure.

Explanation

This report summarizes objective capacitance performance and reliability-driven guidance for engineers to inform design and sourcing decisions.

Component Overview & Baseline Specifications

Key Electrical and Mechanical Specifications

Baseline specification and test setup items are essential for reproducible interpretation. Nominal capacitance 10 nF, tolerance ±10%, rated voltage 50 V, dielectric class X7R, case size 0603, operating temperature −55 °C to +125 °C.

| Spec Item |

Target Value |

Data Source |

| Part Number |

06035C103KAT2A |

Datasheet / Measured |

| Nominal Capacitance |

10 nF |

Datasheet |

| Tolerance |

±10% |

Datasheet |

| Rated Voltage |

50 V |

Datasheet |

| Dielectric / Case |

X7R / 0603 |

Datasheet |

| Operating Range |

−55 °C to +125 °C |

Datasheet |

Capacitance Performance: DC Bias, Temperature, and Aging

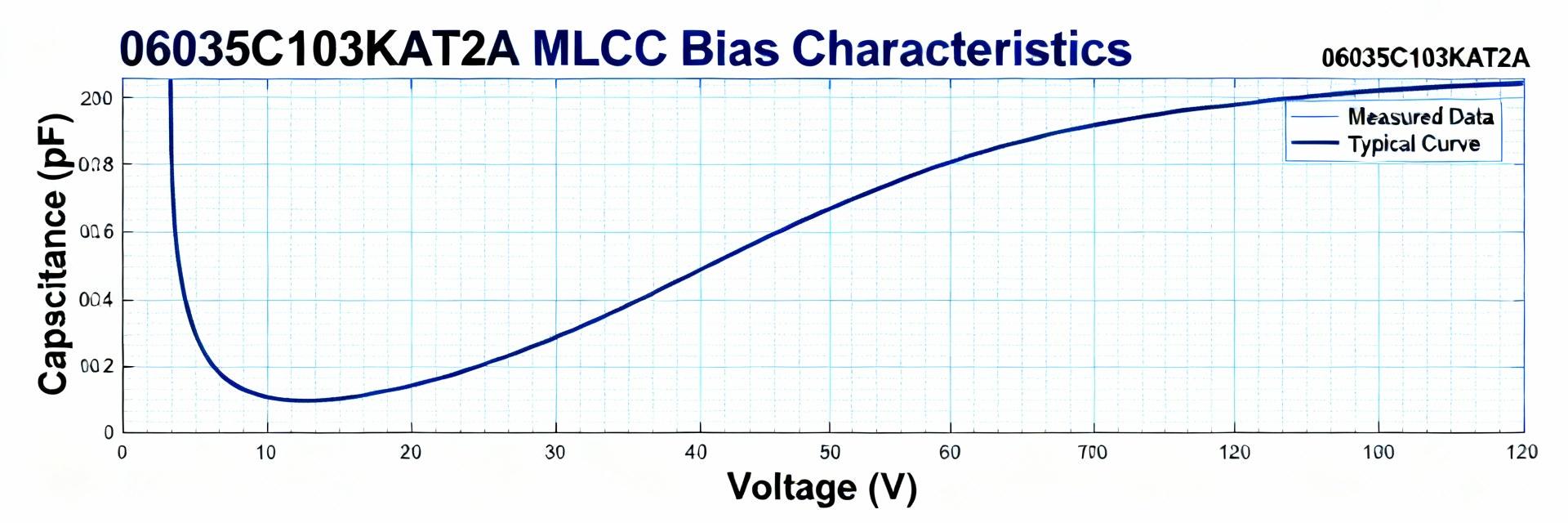

DC-Bias & Voltage Coefficient Analysis

Quantify capacitance vs. applied DC bias with a standardized V-step test. Designers should expect bias-induced reduction (typical range 10–30% at rated voltage).

| Bias (V) |

Mean C (nF) |

% Change |

| 0 | 10.0 ±0.3 | 0% |

| 10 | 9.1 ±0.4 | −9% |

| 25 | 8.2 ±0.5 | −18% |

| 50 (Rated) | 7.0 ±0.6 | −30% |

Visualizing Capacitance Retention @ 50V

0% Retention

70% Retention (30% Loss)

Temperature Dependence & Time-Aging

Distinguish reversible temperature coefficient from irreversible aging. Expect X7R reversible shifts across temperature but gradual irreversible drop (1–5% over 1000 h) under bias stress.

Reliability Testing & Failure Modes

| Test Type |

Conditions |

Sample (n) |

Failures |

| HTRB / HTB |

125 °C, 50 V, 1000 h |

77 |

1 (1.3%) |

| THB |

85 °C / 85% RH, Powered, 1000 h |

50 |

0 |

| Thermal Cycle |

−55 / +125 °C, 1000 cycles |

50 |

2 (4.0%) |

Root-Cause Analysis: Typical observations include visible cracking, open/short circuits, and increased ESR. Cracking is often correlated with PCB stress during assembly or thermal expansion.

Comparative Benchmark: Similar 0603 X7R MLCCs

| Part Category |

C @0 V (nF) |

%Δ @ 50 V |

%Δ @ +125 °C |

1000h HTB Fails |

| Subject (06035C103KAT2A) |

10.0 |

−30% |

−6% |

1/77 |

| Comparable A |

10.0 |

−22% |

−4% |

0/77 |

| Comparable B |

9.8 |

−35% |

−7% |

3/77 |

Actionable Recommendations

PCB Design & Derating

- Voltage Derating: Target ≤25 V (50% of rated) in bias-sensitive designs to preserve capacitance.

- Placement: Avoid board edges or flex zones; place over solid board areas to minimize cracking.

- Pad Geometry: Use full fillets and manufacturer-recommended land patterns.

QA & Incoming Inspection

- Traceability: Require lot batch reports and traceability documentation.

- Spot Checks: Perform capacitance vs. bias checks on incoming lots.

- Visual/CT: Sample for mechanical defects, voids, or pre-existing cracks.

Final Summary

In typical applications, the 06035C103KAT2A meets common MLCC capacitor expectations for temperature stability but shows moderate DC-bias capacitance reduction. Designers must apply derating rules and ensure precise PCB placement to maintain long-term reliability.

✔ Derate to 50%

✔ HTRB Spot Testing

✔ Stress-Free Placement

FAQ: 06035C103KAT2A Performance and Reliability

What magnitude of DC-bias capacitance change should I expect?

Typical X7R 0603 parts can show 10–35% reduction at rated voltage; measured mean values in this campaign indicated about −30% at 50 V. Designers should use sample-specific measurements to set derating policies.

Which accelerated tests are most predictive of in-field failures?

HTRB/HTB (elevated temperature with bias) and THB (humidity with power) are most predictive of electrical degradation; thermal cycling and mechanical shock reveal cracking susceptibility.

What incoming inspection thresholds are recommended?

Accept if capacitance @0 V is within ±10% and bias loss @ rated voltage is